Fulfilling customer wishes, thinking ahead, or even exceeding customer requirements: with this aspiration, ALTANA offers innovative 3D printing materials for additive manufacturing in industry.

We are setting new standards for industrial 3D printing. As one of the leading international specialty chemicals companies, ALTANA offers you highly innovative UV-curable resins and inks for DLP, LCD, SLA and material jetting 3D printing technologies. We address industrial relevant properties, such as reduced environmental ageing, flame-retardancy, heat resistance, impact strength, true elasticity and ESD capability. When it comes to material jetting, sets of compatible inks specially designed for multimaterial 3D printing are available including a broad range of properties, colors and the relevant water-soluble or water-breakable support materials.

Cubic Ink®

Mold 2000 VP

Water-breakable cast material compatible with various (2K-)filling compounds

Cubic Ink® Mold 2000 VP is the material of choice for cast applications with molten and a variety of 2K filling compounds, e.g. 2K silicones, epoxides, polyurethanes, polyesters as well as low-melting metals and alloys. Highlight of this material is its water-breakable character allowing a complete breakup of the mold material when exposed to water. Thus, our material allows for the generation of complex and fine structures which are hardly achievable with conventional casting materials. Moreover, since the manual removal is not necessary anymore, the mold materials are an enabler for an automized fill and remove process.

Materials can be used in

Performance Indicators

| Compatible Filling-Materials | Various 1 and 2K Materials |

| Solubility in Water or Aqueous Media | Very Good |

| Print Accuracy | Very Good |

| Minimum Wall Thickness (Mold) | 200 μm |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Transparent, Colors on Demand |

| Washing | IPA or Ethanol |

| Post-Processing | UV Post-Cure |

| Mold Removal | Water, or Diluted Alkalic Media |

Cubic Ink®

Mold 3000 VP

Water-breakable cast material for injection molding applications

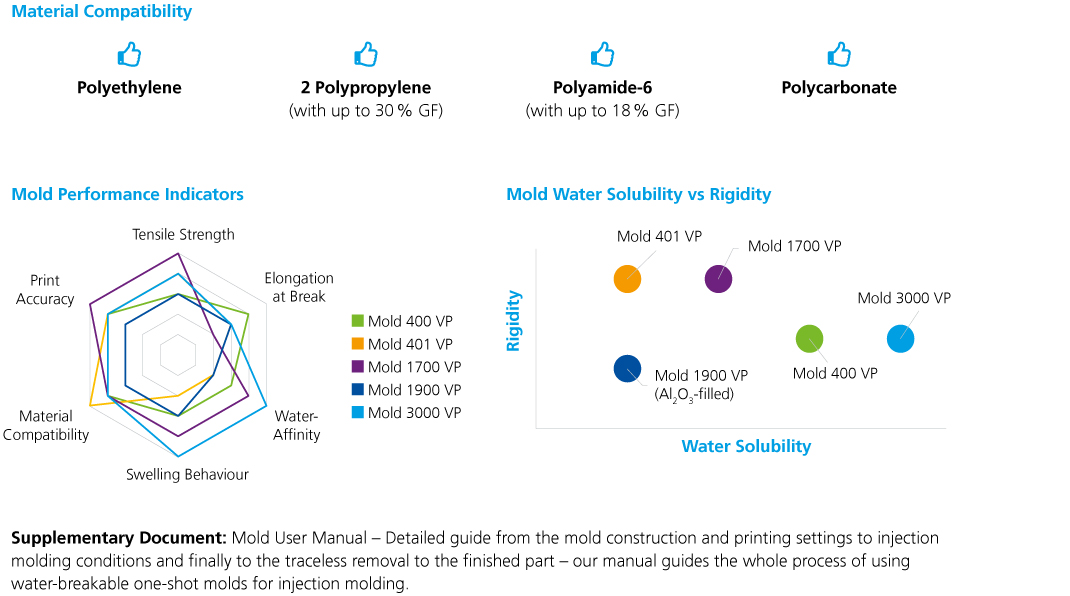

Cubic Ink® Mold 3000 VP is s our newest product in the series of One-Shot-Molds (OSMs) for usage in injection molding applications tolerating high temperature and pressure conditions. Our material has proven excellent compatibility with typical filling materials, e.g. PE, PP, PA6(-GF) and PC providingvery good accuracy in the final object. The improved water-affinity allows for an easy mold removal in water or aqueous media. Moreover, undesired swelling behaviour is reduced to a minimum, which protects the final part from deformation or cracking.

Materials can be used in

Performance Indicators

| Max Temperature at Injection Nozzle | 320°C |

| Max Injection Pressure | 800 bar |

| Min Thickness Filling Material | 100 μm |

| Swelling in Water | Minimal |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Transparent, Colors on Demand |

| Washing | IPA or Ethanol |

| Post-Processing | UV Post-Cure |

| Mold Removal | Water, or Diluted Alkalic Media |

Technical Details

Cubic Ink®

Rigid 300 VP

Rigid materials for functional prototyping

This class of materials is not only customizable in rigidity and hardness, but also allows maximum design freedom and delivers sharp details thanks to its low viscosity. It is ideal for robust applications and has a good thermal long-term stability.

Materials can be used in

Performance Indicators

| Tensile Strength | 57 MPa |

| Tensile Modulus | 2,600 MPa |

| Elongation at Break | 4.3% |

| Shore Hardness | 82 D |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Black, more on Demand |

| Washing | IPA |

| Post-Processing | UV Post-Cure |

Technical Details

Cubic Ink®

Rigid 300 VP High Resolution

Rigid material for high precision printing

Cubic Ink® Rigid 300 VP High Resolution allows for printing with ultra-thin layers and a crisp XY-resolution while offering high print speeds due to its reactivity. Its low water uptake ensures dimensional stability in permanent contact to fluids.

Materials can be used in

Performance Indicators

| Tensile Strength | 37 MPa |

| Elongation at Break | 8% |

| Depth of Penetration | 0.08/0.10 |

Water Uptake, 24h, 23 °C | 0.3% |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Translucent Yellow |

| Washing | IPA |

| Post-Processing | UV Post-Cure |

Cubic Ink®

Rigid 404 VP-Clear

Transparent and colorless materials

Cubic Ink® Rigid 404 VP-Clear is designed for applications where a high transparency and clarity is needed. Other optical properties such as the refractive index along with the mechanical properties can be customized.

Materials can be used in

Performance Indicators

| Tensile Strength | 55 MPa |

| Elongation at Break | 4.4% |

| Optical Appearance | Exceptional Clarity |

| Refractive Index | on Demand |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Colorless, on Demand |

| Washing | IPA |

| Post-Processing | UV Post-Cure |

Cubic Ink®

Tough 1900 VP

All-round material with balanced properties

Cubic Ink® Tough 1900 VP is designed as a general purpose solution with excellent definition, a balanced set of mechanical properties and can be easily colored.It is of low viscosity and allows fast and reliable printing with maximum design freedom.

Materials can be used in

Performance Indicators

| Tensile Strength | 30 MPa |

| Tensile Modulus | 1,300 MPa |

| Elongation at Break | 24% |

| Izod notched | 22 J/m |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Grey, more on Demand |

| Washing | IPA |

| Post-Processing | UV Post-Cure |

Cubic Ink®

Dental 3000 VP

Material for dental models

Cubic Ink® Dental 3000 VP is designed for fast and high-resolution printing. Fine-tuned mechanical and thermo-mechanical properties, application-specific color and scalable pricing make this material an excellent model material for the dental industry. Printable with up to 150 microns.

Materials can be used in

Performance Indicators

| Flexural Strength | 83 MPa |

| Flexural Modulus | 2,200 MPa |

| Deflection at Fracture | > 10% |

| Shore Hardness | 85 D |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Ivory White, more on Demand |

| Washing | IPA |

| Post-Processing | UV Post-Cure |

Cubic Ink®

Flexible 1400 VP

Very soft and flexible material

Cubic Ink® Flexible material family groups resins with adaptable hardness, elasticity and colors in the Shore A range. Flexible 1400 VP has a Shore A of 30 while being processable on both common open DLP and LCD printers.

Materials can be used in

Performance Indicators

| Shore Hardness | 30 A |

| Compression Set-B | < 5% |

| Elongation at Break | 160% |

| Tensile Strength | 2.6 MPa |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | on Demand |

| Washing | IPA |

| Post-Processing | UV Post-Cure |

Cubic Ink®

High Temperature 200 VP

Material with very high heat resistance

Cubic Ink® High Temperature materials with very easy and versatile processability show high printing accuracy. Due to superior thermal and chemical stabilities with heat deflection temperatures above 300°C and no brittleness the materials are designed, and yet customizable, for demanding applications at elevated temperatures up to 250°C.

Materials can be used in

Performance Indicators

| HDT B | > 300°C |

| Chemical Resistance | Superior |

| CTE (0 – 250 °C) | 70 x 10-6 K-1 |

| E-Modul | 4,500 MPa |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | on Demand |

| Washing | IPA |

| Post-Processing | UV and/or Thermal Post-Cure |

Cubic Ink®

High Temperature 303 VP-ESD Black

ESD material with very high heat resistance

Cubic Ink® High Temperature ESD materials meet customers ESD-requirements and target applications where high heat and chemical resistance is necessary. The materials are fairly low viscous and versatile processabile in terms of printer and post-curing.

Materials can be used in

Performance Indicators

| Volume Resistivity | 6.6 x 107 Ω·cm |

| HDT A | 216°C |

| Chemical resistance | Very Good |

| Thermal stability | Verry Good |

Processing Guide

| Printing Technology | DLP and LCD |

| Color | Black |

| Washing | IPA |

| Post-Processing | UV and/or Thermal Post-Cure |

Cubic Ink®

High Performance 1-202 VP

Thermal form stable material

With thermal form stabilities over 190°C these materials are designed for demanding applications at very high temperatures. Additionally, this material family maintains its strong character over a long period at elevated temperatures.

Materials can be used in

Performance Indicators

| HDT B | 195°C |

| Flexural Strength | 130 MPa |

| Elongation at Break | 3.5% |

| Flammability | HB |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Black, Intrinsic |

| Washing | IPA |

| Post-Processing | UV and thermal Post-Cure |

Cubic Ink®

High Performance 2-900 VP

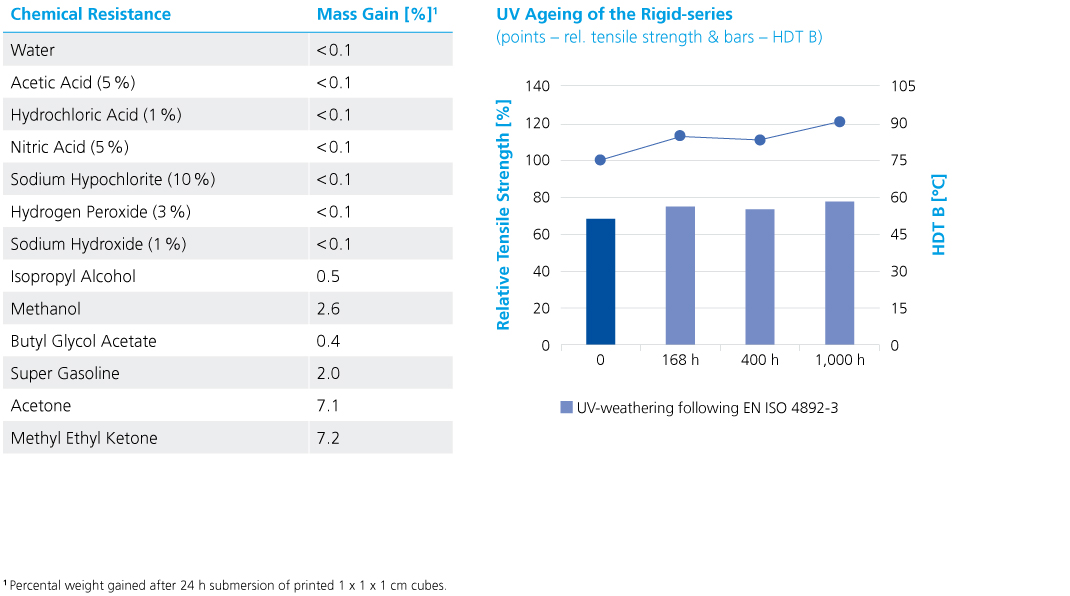

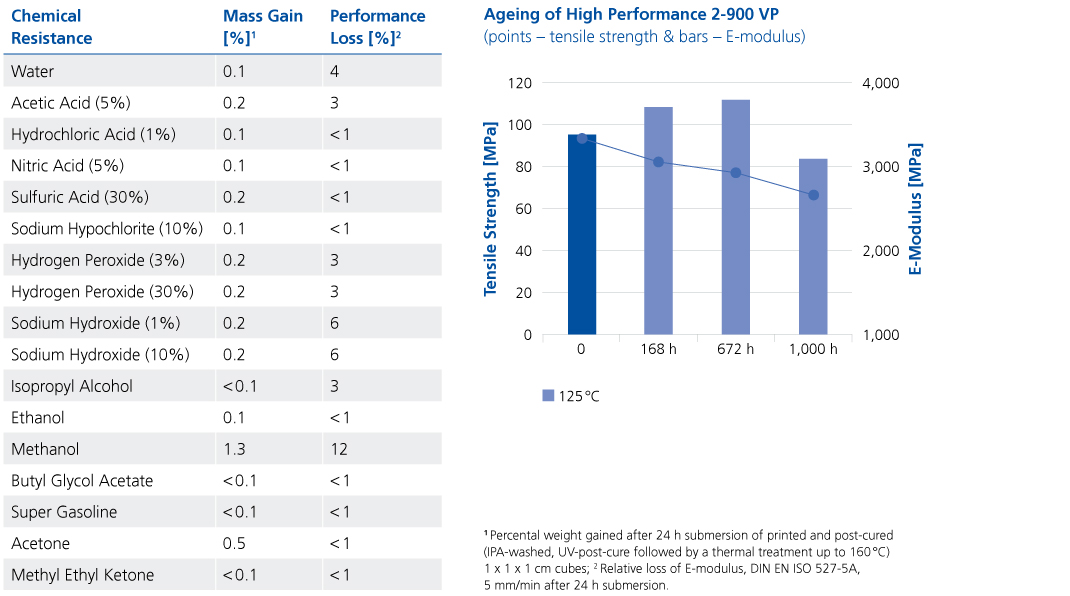

Material for chemically challenging surroundings

Chemical very resistant materials in various industrial fluids including a broad range of customizable mechanical and thermo-mechanical properties for final part production. The inherent decent viscosity and good pot-life allows fast printing and easy handling in the printing process.

Materials can be used in

Performance Indicators

| Chemical Resistance | Superior |

| HDT B | 138°C |

| Flexural Strength | 118 MPa |

| Dielectric Strength | 25 kV/mm |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Black, Red, Intrinsic |

| Washing | IPA |

| Post-Processing | UV and Thermal Post-Cure |

Technical Details

Cubic Ink®

High Performance 2-1400 VP

Transparent allround material for stereolithography

Cubic Ink® High Performance 2-1400 VP is a transparent material with a balanced set of mechanical and thermo-mechanical properties. It has a very low water uptake, a good surface finish and low shrinkage. This material is especially designed to be used on stereolithography printers. Available in different colors and shades.

Materials can be used in

Performance Indicators

| Water Uptake | < 0.1 |

| Chemical Resistance | Very Good |

| Izod notched | 38 J/m |

| Shrinkage | Less |

Processing Guide

| Printing Technology | SLA |

| Color | Transparent, Black, on Demand |

| Washing | PC/IPA |

| Post-Processing | UV Post-Cure |

Technical Details

Cubic Ink®

High Performance 3-1700 VP

Elastic and tear resistant material with a very low water uptake

Cubic Ink® High Performance 3-1700 VP is an elastic material with outstanding low water-uptake, a broad range of operating temperature, a competitive UV- and temperature ageing stability and a high tear strength. It comes in a moderate viscosity and has long-time pot-life even at elevated temperatures.

Materials can be used in

Performance Indicators

| Tear Strength | 120 kN/m |

| Thermal Stability | Over broad Temp. Range |

| Chemical Resistance | Very Good |

| Rebound | 30% |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Black, Grey, Green, Intrinsic |

| Washing | DPM/IPA |

| Post-Processing | Thermal Post-Cure |

Technical Details

Cubic Ink®

High Performance 4

Technical All-round Materials

Highly versatile technical all-round materials with good impact resistance, high thermal form stability and scratch resistance

Cubic Ink® High Performance 4 materials were designed for applications where a combination of good impact strength and toughness with thermal form-stability and elasticity is needed. Additionally, an outstanding scratch resistant surface makes these technical all-round materials a customer's choice for final part production. The resins' low viscosity allow fast and accurate printing while maintain a high degree of customization depending on customer's needs such as high impact resistance, flexibility, cytotoxicity, ESD-character or flame retardancy.

Performance Indicators

| Izod notched | 25 – 70 J/m |

| HDT B | 70 – 100°C |

| Elongation at Break | 5 – 70% |

| Cytotoxicity | on Request |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | on Demand |

| Washing | Water |

| Post-Processing | UV and/or Thermal Post-Cure |

Technical Datasheets

| HP 4-300 VP | Technical datasheet |

| HP 4-3800 VP | Technical datasheet |

| HP 4-6700 VP | Technical datasheet |

| HP 4-4800 VP Black | Technical datasheet |

| HP 4-2100 VP | Technical datasheet |

Cubic Ink® High Performance

4-2800 VP-ESD Black

ESD material with excellent processability and low viscosity

Cubic Ink® ESD materials are designed to meet the customer´s ESD requirements. Thanks to their low viscosity a very good processability is given. The tough yet customizable range of properties of these materials makes them a good choice for a broad range of applications.

Materials can be used in

Performance Indicators

| Volume Resistivity | 1.8 x 107 Ωcm |

| HDT B | 94°C |

| Elongation at Break | 4.0% |

| Chemical Resistance | Very Good |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Black |

| Washing | Water |

| Post-Processing | UV and/or Thermal Post-Cure |

Technical Details

Cubic Ink®

High Performance

4-1000 VP-V0

UL 94 V0-certified material

Cubic Ink@ HP 4-1000 VP-V0 is a flame retardant material with high rigidity. It is V-0 according to UL 94 and its low viscosity results in very good processability and maximal design freedom.

Materials can be used in

Performance Indicators

| Flammability | V-0 |

| Viscosity | Low |

| HDT B | 123°C |

| Tensile Strength | 97 MPa |

Processing Guide

| Printing Technology | DLP, LCD and SLA |

| Color | Black, Grey, Intrinsic |

| Washing | Water |

| Post-Processing | UV and Thermal Post-Cure |

Technical Details

Support Materials

Easily to remove support materials

Cubic Ink® Support materials are water-soluble or water-breakable. They can be removed automatically in a water bath without chemical solvents or manually with low force. These materials are designed to give a high resolution and ease of process. The hardness and the dissolution times are adjustable.

Materials can be used in

Performance Indicators

| Dissolution Time | Variable |

| Viscosity | 10 – 1,000 mPa-s |

| Shore Hardness | 30 A – 60 D |

Support removal1

| Dissolution time - Support 3800 | 2 hours |

| Dissolution time - Support 1201 | 5 hours |

| Dissolution time - Support 2700 | 15 hours |

| Dissolution time - Support 2701 | 50 hours |

1Time until total dissolution of support based on a model geometry in water at 40°C and ultra-sound.

Cubic Ink®

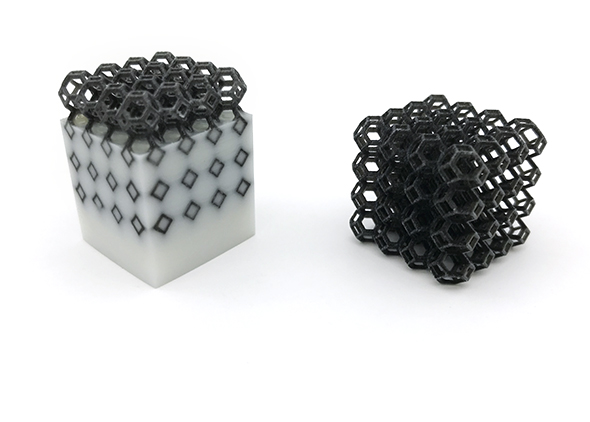

Flexible and Rigid Multi-Material Capacity

UV curable inks for material jetting

Benefit from the possibilities of Material Jetting with the Cubic Ink® versatile portfolio. Based upon our deep understanding and experience regarding low viscosity fluids, we can offer a broad range of inks for various end-uses. In addition to the standard CMYK and white colors, we can customize the color to your needs.

Materials can be used in

Performance Indicators

| Shore Hardness | 30 A - 85 D |

| Elongation at Break | 3 - 350% |

Processing Guide

| Printing Technology | Material Jetting |

| Color | CMYK, White, Spot Color |

| Washing | Water |

| Post-Processing | UV |

For more information regarding Flexible and Rigid Materials for Material Jetting please contact us via cubic.ink@altana.com

Cubic Ink®

High Performance 4-1203

Technical all-round material with a HDT B up to 100°C

Cubic Ink® High Performance 4-1203 shows a good balance between temperature form-stability and toughness for final part production including passing horizontal-burning tests.

Materials can be used in

Performance Indicators

| HDT B | 100°C |

| Elongation at Break | 6% |

| Flammability | HB |

| Flexural Strength | 118 MPa |

Processing Guide

| Printing Technology | Material Jetting |

| Color | Black, Intrinsic, on Demand |

| Post-Processing | UV and/or Thermal Post-Cure |

Cubic Ink® at Rapid + TCT 2025 in Detroit

See us on booth 1946

The Cubic Ink® Team from ALTANA New Technologies GmbH will introduce its materials for DLP, LCD and SLA printing technology on Rapid+TCT.

Come by and be introduced into Cubic Inks portfolio of High Performance, High Temperature and Mold materials.

We give shape to ideas®

Cooperation of competencies

ALTANA's Cubic Ink® team consists of employees with diverse experience not only in chemistry, but also in printing technology and application. Cubic Ink® 3D printing materials are created in close cooperation with partners and customers in additive manufacturing. Cubic Ink® benefits not only from existing structures of the ALTANA group, but also from the broad chemistry knowledge of all business units including Scale-Up, Production, Regulatory, Logistics, Legal and Marketing.

Service and process know-how

As a pioneer in material development, ALTANA focuses on industrial application and customer added value. This also means that materials can be adapted to specific customers and applications. Our printing and process know-how as well as our machinery consisting of state-of-the-art DLP, LCD, SLA and material jetting 3D printers enable processing on all common printing systems. Cubic Ink® materials are not only tested internally in the important process steps such as washing and post-exposure/post-curing, but also comprehensively and extensively characterized with regard to all important performance indicators.

High-performance materials and industrial mindset

With Cubic Ink®, ALTANA offers a steadily growing resin and ink portfolio for use in all common UV curing-based 3D printing technologies: DLP, LCD, SLA and Material Jetting. These are materials that stand out in your property profile in the market. Some of our focus topics are reduced ageing, chemical resistance and elasticity. In material jetting, various material systems with mutlimaterial capability are available for a wide range of inkjet systems.

ALTANA's Cubic Ink® team consists of employees with diverse experience not only in chemistry, but also in printing technology and application. Cubic Ink® 3D printing materials are created in close cooperation with partners and customers in additive manufacturing. Cubic Ink® benefits not only from existing structures of the ALTANA group, but also from the broad chemistry knowledge of all business units including Scale-Up, Production, Regulatory, Logistics, Legal and Marketing.

As a pioneer in material development, ALTANA focuses on industrial application and customer added value. This also means that materials can be adapted to specific customers and applications. Our printing and process know-how as well as our machinery consisting of state-of-the-art DLP, LCD, SLA and material jetting 3D printers enable processing on all common printing systems. Cubic Ink® materials are not only tested internally in the important process steps such as washing and post-exposure/post-curing, but also comprehensively and extensively characterized with regard to all important performance indicators.

With Cubic Ink®, ALTANA offers a steadily growing resin and ink portfolio for use in all common UV curing-based 3D printing technologies: DLP, LCD, SLA and Material Jetting. These are materials that stand out in your property profile in the market. Some of our focus topics are reduced ageing, chemical resistance and elasticity. In material jetting, various material systems with mutlimaterial capability are available for a wide range of inkjet systems.

Do you have any questions? We are here to assist you. Please don't hesitate to reach out if you need any help or information. You can contact us at cubic.ink@altana.com. We look forward to hearing from you soon and providing the support you need.