Inks for Functional Prototyping, Supports and Special Applications

Materials for multimaterial 3D printing

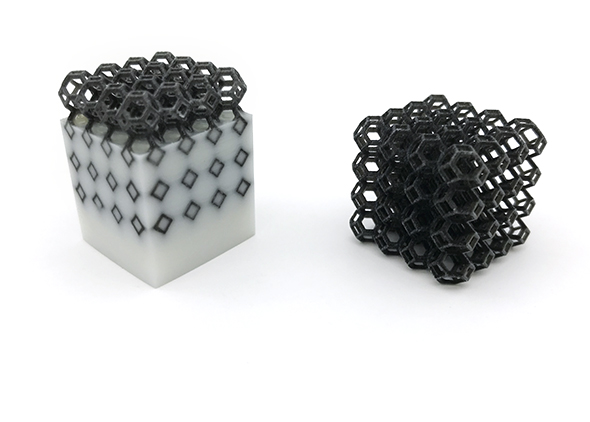

Support Materials

Easily to remove support materials

Cubic Ink® Support materials are water-soluble or water-breakable. They can be removed automatically in a water bath without chemical solvents or manually with low force. These materials are designed to give a high resolution and ease of process. The hardness and the dissolution times are adjustable.

Materials can be used in

Performance Indicators

| Dissolution Time | Variable |

| Viscosity | 10 – 1,000 mPa-s |

| Shore Hardness | 30 A – 60 D |

Support removal1

| Dissolution time - Support 3800 | 2 hours |

| Dissolution time - Support 1201 | 5 hours |

| Dissolution time - Support 2700 | 15 hours |

| Dissolution time - Support 2701 | 50 hours |

1Time until total dissolution of support based on a model geometry in water at 40°C and ultra-sound.

Cubic Ink®

Flexible and Rigid Multi-Material Capacity

UV curable inks for material jetting

Benefit from the possibilities of Material Jetting with the Cubic Ink® versatile portfolio. Based upon our deep understanding and experience regarding low viscosity fluids, we can offer a broad range of inks for various end-uses. In addition to the standard CMYK and white colors, we can customize the color to your needs.

Materials can be used in

Performance Indicators

| Shore Hardness | 30 A - 85 D |

| Elongation at Break | 3 - 350% |

Processing Guide

| Printing Technology | Material Jetting |

| Color | CMYK, White, Spot Color |

| Washing | Water |

| Post-Processing | UV |

For more information regarding Flexible and Rigid Materials for Material Jetting please contact us via cubic.ink@altana.com

Cubic Ink®

High Performance 4-1203

Technical all-round material with a HDT B up to 100°C

Cubic Ink® High Performance 4-1203 shows a good balance between temperature form-stability and toughness for final part production including passing horizontal-burning tests.

Materials can be used in

Performance Indicators

| HDT B | 100°C |

| Elongation at Break | 6% |

| Flammability | HB |

| Flexural Strength | 118 MPa |

Processing Guide

| Printing Technology | Material Jetting |

| Color | Black, Intrinsic, on Demand |

| Post-Processing | UV and/or Thermal Post-Cure |

Do you have any questions? We are here to assist you. Please don't hesitate to reach out if you need any help or information. You can contact us at cubic.ink@altana.com. We look forward to hearing from you soon and providing the support you need.